Tuesday, 25 March 2025 15:20

Why Rochester Accounting LTD is the Best Choice for Your Small Business Accounting Needs

Introduction The Small Business Accounting Challenge

Running a small business in the UK presents numerous challenges, with accounting and financial management often ranking among the most complex and time-consuming responsibilities. From navigating constantly evolving tax regulations to managing cash flow effectively, the financial aspects of business ownership can quickly become overwhelming. This is where selecting the right accounting partner becomes crucial for sustainable growth and success.

Published in

Business

Wednesday, 22 January 2025 16:01

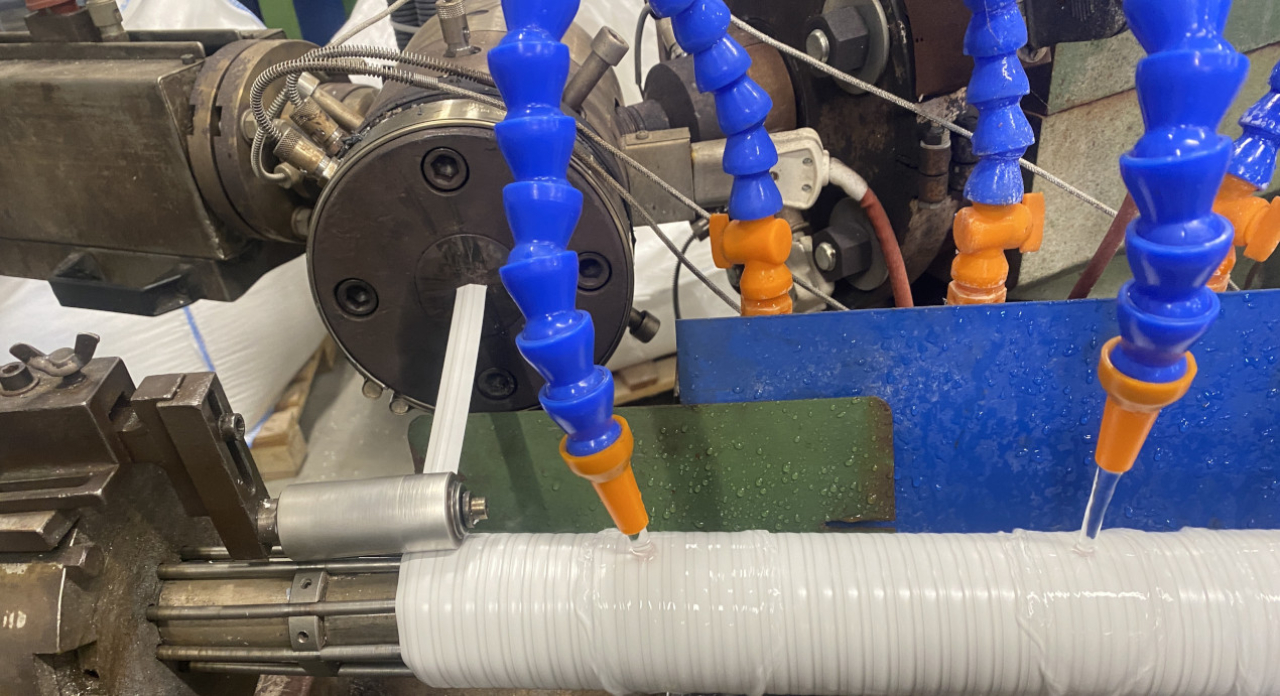

Rubber Profiles and Noise Insulation Solutions for the Automotive Industry – ST Plastics

At ST Plastics, we specialize in the production of rubber profiles, seals, and noise insulation solutions for the automotive industry. Our products are designed to meet the highest standards of performance, precision, and durability, contributing to improved vehicle integration and quality.

Published in

Business